Advance Ply

Palladium

- Home

- Advance Ply Palladium

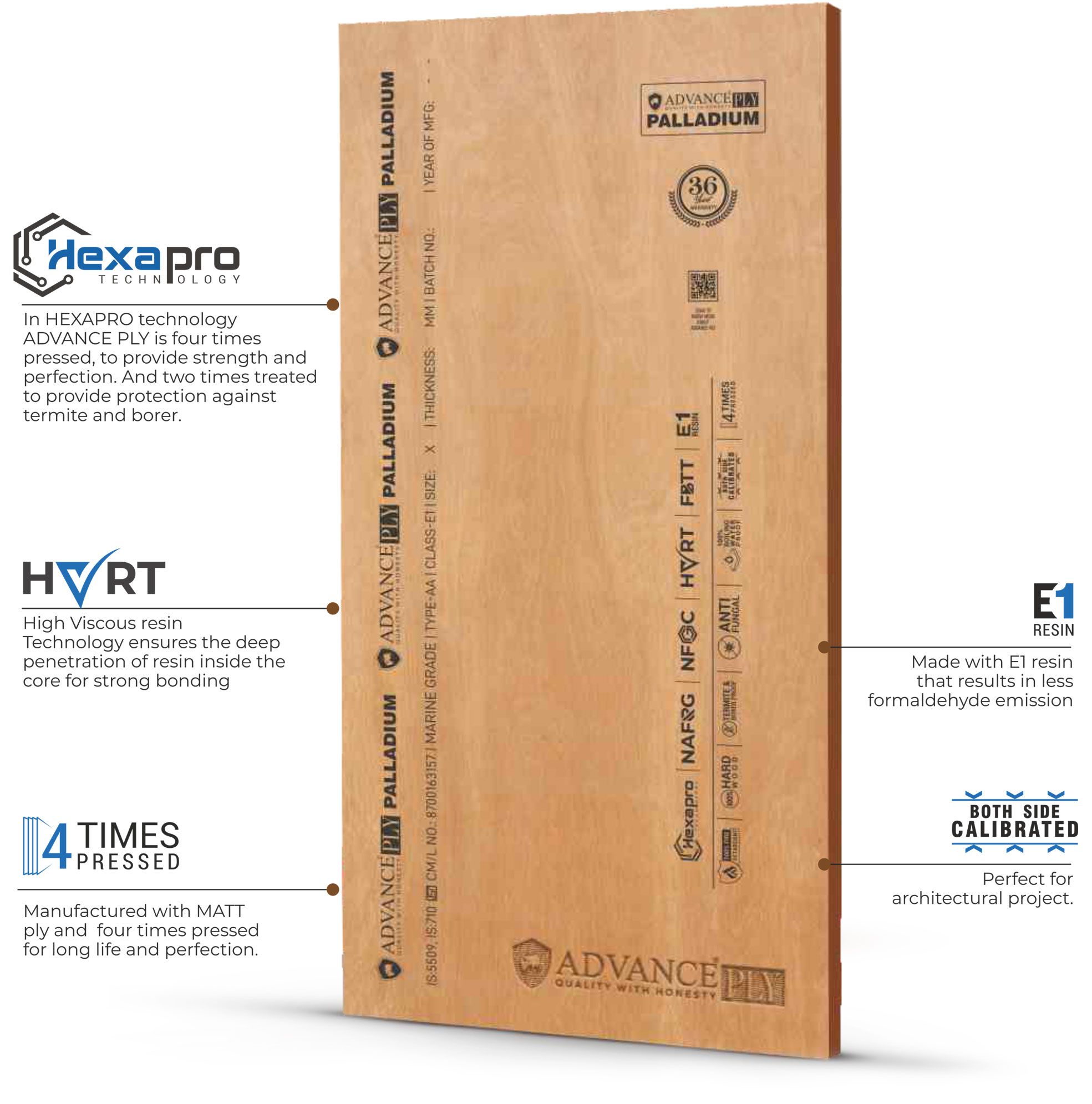

MADE WITH E1 GRADE RESIN, BOILING WATER PROOF, MARINE GRADE, IS:710, FULLY HARDWOOD CONSTRUCTION

Features

- E1 MPF MARINE Grade Resin

- IS: 710 Grade

- Boiling water resistance for >200hrs

- All Glue Line Treated with Anti Borer, Termite & Fungi Chemicals

- High Viscosity Resin Technology

Advantages

- Water proof grade bonding

- Marine grade plywood

- Long lasting bond even under high moisture or humidity

- Stops insects and fungus from attacking the plywood

- Helps even spreading of resin Leading to perfect bond between layers

Benefits

- Low in Emission, strong in Water Proofing

- Can be used in Exterior conditions or severe humid environments

- Very high water-proofing and longevity of products

- No powders formation decay or termite Attack on your furniture

- Uniform Bonding and Strength of plywood

Technical Specifcation for Marine Grade Plywood

Base Material

Hardwood

Face material

Tropical hardwood Species

Glue/Adhesion

Bonded with Phenol formaldehyde resin with provides boiling water proof

Calibrated

Yes

Compliance standard

Conforms to IS 710, Marine Grade

Thickness Range

ommonly available in 6mm to 19mm

Standard Size

Sheet typically comes in such as 8×4, 7×4, 6×4, 8×3, 7×3, 6×3 ft.

Density

Avg density – 0.75g/cm 3

water proof

Boiling water proof

Moisture Content

5 ~ 15% in oven dry method

Formaldehyde emission type

E1 Grade

CCB Treated

Core treated with Copper, Chrome, Boron

Weather Resistance

Withstand adverse climatic conditions

Screw holding capacity

More than 1600 N

Retention of Preservative

12.5kg/m3

Fire Resistance

Flame penetration – More than 60 min., Flammability – More than 45 min., Rate of burning – More than 30 min.

Modulus of Elasticity-Dry state

Along the grain – Avg – 6589 N/mm2, Min – 6036 N/mm2, Across the grain – Avg – 4890 N/mm2, Min – 4352 N/mm2

Modulus of rupture-Dry state

Along the grain – Avg – 49 N/mm2, Min – 43 N/mm2